ACCURACY AND PRECISION

We know that accuracy of measurement is very important for manufacturing a quality product. Accuracy is the degree of agreement of the measured dimension with its true magnitude. It can also be defined as the maximum amount by which the result differs from the true value or as the nearness of the measured value to its true value, often expressed as a percentage. True value may be defined as the mean of the infinite number of measured values when the average deviation due to the various contributing factors tends to zero. In practice, realization of the true value is not possible due to uncertainties of the measuring process and hence cannot be determined experimentally. Positive and negative deviations from the true value are not equal and will not cancel each other. One would never know whether the quantity being measured is the true value of the quantity or not.

Precision is the degree of repetitiveness of the measuring process. It is the degree of agreement of the repeated measurements of a quantity made by using the same method, under similar conditions. In other words, precision is the repeatability of the measuring process. The ability of the measuring instrument to repeat the same results during the act of measurements for the same quantity is known as repeatability. Repeatability is random in nature and, by itself, does not assure accuracy, though it is a desirable characteristic. Precision refers to the consistent reproducibility of a measurement. Reproducibility is normally specified in terms of a scale reading over a given period of time. If an instrument is not precise, it would give different results for the same dimension for repeated readings. In most measurements, precision assumes more significance than accuracy. It is important to note that the scale used for the measurement must be appropriate and conform to an internationally accepted standard.

It is essential to know the difference between precision and accuracy. Accuracy gives information regarding how far the measured value is with respect to the true value, whereas precision indicates quality of measurement, without giving any assurance that the measurement is correct. These concepts are directly related to random and systematic measurement errors.

Figure 1.1 also clearly depicts the difference between precision and accuracy, wherein several measurements are made on a component using different types of instruments and the results plotted.

It can clearly be seen from Fig. 1.1 that precision is not a single measurement but is associated with a process or set of measurements. Normally, in any set of measurements performed by the same instrument on the same component, individual measurements are distributed around the mean value and precision is the agreement of these values with each other. The difference (a) (b) (c) (d)

Fig. 1.1 Accuracy and precision (a) Precise but not accurate (b) Accurate but not precise (c) Precise and accurate (d) Not precise and not accuratebetween the true value and the mean value of the set of readings on the same component is termed as an error. Error can also be defined as the difference between the indicated value and the true value of the quantity measured.

E = Vm − Vt

where E is the error, Vm the measured value, and Vt the true value.

The value of E is also known as the absolute error. For example, when the weight being measured is of the order of 1 kg, an error of ±2 g can be neglected, but the same error of ±2 g becomes very significant while measuring a weight of 10g. Thus, it can be mentioned here that for the same value of error, its distribution becomes significant when the quantity being measured is small. Hence, % error is sometimes known as relative error. Relative error is expressed as the ratio of the error to the true value of the quantity to be measured. Accuracy of an instrument can also be expressed as % error. If an instrument measures Vm instead of Vt, then,

% error = Error /True value × 100

Or % error = Vm − Vt / Vt × 100

Accuracy of an instrument is always assessed in terms of error. The instrument is more accurate if the magnitude of error is low. It is essential to evaluate the magnitude of error by other means as the true value of the quantity being measured is seldom known, because of the uncertainty associated with the measuring process. In order to estimate the uncertainty of the measuring process, one needs to consider the systematic and constant errors along with other factors that contribute to the uncertainty due to scatter of results about the mean. Consequently, when precision is an important criterion, mating components are manufactured in a single plant and measurements are obtained with the same standards and internal measuring precision, to accomplish interchangeability of manufacture. If mating components are manufactured at different plants and assembled elsewhere, the accuracy of the measurement of two plants with true standard value becomes significant.

In order to maintain the quality of manufactured components, accuracy of measurement is an important characteristic. Therefore, it becomes essential to know the different factors that affect accuracy. Sense factor affects accuracy of measurement, be it the sense of feel or sight. In instruments having a scale and a pointer, the accuracy of measurement depends upon the threshold effect, that is, the pointer is either just moving or just not moving. Since accuracy of measurement is always associated with some error, it is essential to design the measuring equipment and methods used for measurement in such a way that the error of measurement is minimized.

Two terms are associated with accuracy, especially when one strives for higher accuracy in measuring equipment: sensitivity and consistency. The ratio of the change of instrument indication to the change of quantity being measured is termed as sensitivity. In other words, it is the ability of the measuring equipment to detect small variations in the quantity being measured. When efforts are made to incorporate higher accuracy in measuring equipment, its sensitivity increases. The permitted degree of sensitivity determines the accuracy of the instrument. An instrument cannotbe more accurate than the permitted degree of sensitivity. It is very pertinent to mention here that unnecessary use of a more sensitive instrument for measurement than required is a disadvantage.

When successive readings of the measured quantity obtained from the measuring instrument are same all the time, the equipment is said to be consistent. A highly accurate instrument possesses both sensitivity and consistency. A highly sensitive instrument need not be consistent, and the degree of consistency determines the accuracy of the instrument. An instrument that is both consistent and sensitive need not be accurate, because its scale may have been calibrated with a wrong standard. Errors of measurement will be constant in such instruments, which can be taken care of by calibration. It is also important to note that as the magnification increases, the range of measurement decreases and, at the same time, sensitivity increases. Temperature variations affect an instrument and more skill is required to handle it. Range is defined as the difference between the lower and higher values that an instrument is able to measure. If an instrument has a scale reading of 0.01–100 mm, then the range of the instrument is 0.01–100 mm, that is, the difference between the maximum and the minimum value.

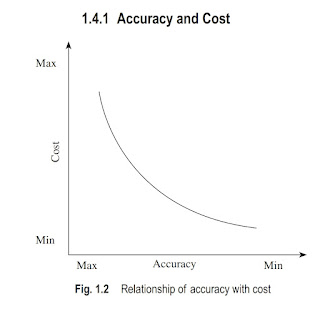

Accuracy and Cost

It can be observed from Fig. 1.2 that as the requirement of accuracy increases, the cost increases exponentially. If the tolerance of a component is to be measured, then the accuracy requirement will normally be 10% of the tolerance values. Demanding high accuracy unless it is absolutely required is not viable, as it increases the cost of the measuring equipment and hence the inspection cost. In addition, it makes the measuring equipment unreliable, because, as discussed in Section 1.4, higher accuracy increases sensitivity. Therefore, in practice, while designing the measuring equipment, the desired/required accuracy to cost considerations depends on the quality and reliability of the component/product and inspection cost.